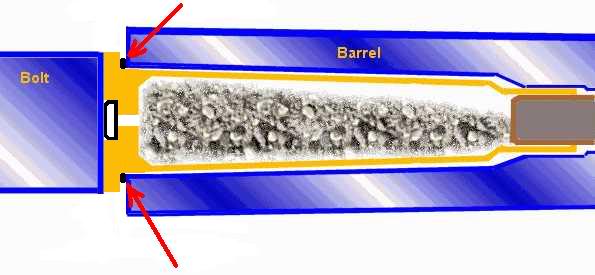

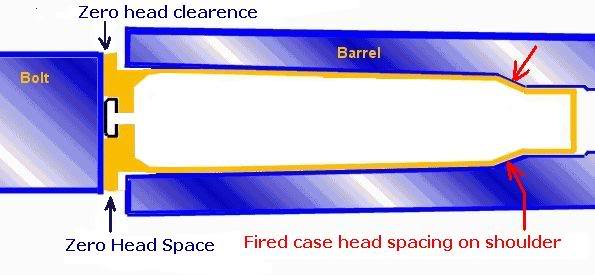

I decided to measure the headspace more carefully, and have now determined that the actual measurement is .076", even longer than the generous Brit maximum, and I'd certainly like to bring it as much nearer to the minimum figure (.064") as possible.

The bolt head measures .629", from the shoulder which contacts the face of the bolt body to the face of the bolt head itself. In order to achieve the desired headspace measurement of .064", I'd need a bolt head which measures .641" - .012" longer than this one. I don't know whether such a measurement is available, but hope so, or that one as close as possible to that length can be found, so as to bring the headspace into the desired (near minimum) range. I thought about making a shim to fit between the bolt body and bolt head, but realized that would throw-off the bolt head timing.

Well, I knew this was a project when I bought the rifle, but I think it's worth the effort.

mhb - MIke

Reply With Quote

Reply With Quote

)

)